The advantages of Silicon Carbide Mechanical Seal Rings:

1. **Exceptional Hardness:** Silicon Carbide (SiC) is known for its remarkable hardness, providing excellent resistance to wear and abrasion. This results in a longer lifespan and reduced maintenance requirements for mechanical seal rings.

2. **High Wear Resistance:** The hardness of SiC translates to high wear resistance, making it particularly effective in applications where friction and wear are significant factors. This is crucial in maintaining the integrity of mechanical seals over extended periods.

3. **Corrosion Resistance:** Silicon Carbide exhibits resistance to corrosion, making it suitable for applications involving aggressive or corrosive fluids. This resistance ensures the longevity of mechanical seal rings even in challenging chemical environments.

4. **Thermal Stability:** SiC has excellent thermal stability, allowing it to withstand high temperatures without compromising its structural integrity. This property is essential in applications where mechanical seals are exposed to elevated temperatures.

5. **Low Coefficient of Friction:** Silicon Carbide has a low coefficient of friction, contributing to reduced frictional heat generation and improved efficiency. This characteristic is beneficial in applications where minimizing heat and energy loss is critical.

6. **Chemical Inertness:** SiC is chemically inert, meaning it does not react with many chemicals. This inertness is advantageous in situations where the mechanical seal is exposed to various chemical substances, ensuring stability and reliability.

7. **High Strength:** Silicon Carbide possesses high strength, allowing mechanical seal rings to withstand substantial mechanical stress and pressure. This strength contributes to the overall robustness and reliability of the seal.

8. **Dimensional Stability:** Silicon Carbide exhibits good dimensional stability under varying conditions, ensuring that the mechanical seal maintains its shape and effectiveness over time. This is crucial for consistent performance in demanding applications.

9. **Reduced Maintenance:** The combination of hardness, wear resistance, and corrosion resistance results in reduced maintenance needs for equipment using Silicon Carbide Mechanical Seal Rings. This leads to cost savings and increased operational efficiency.

In summary, Silicon Carbide Mechanical Seal Rings offer a comprehensive set of advantages, making them ideal for demanding applications where durability, reliability, and performance are critical factors.

1. **Exceptional Hardness:** Silicon Carbide (SiC) is known for its remarkable hardness, providing excellent resistance to wear and abrasion. This results in a longer lifespan and reduced maintenance requirements for mechanical seal rings.

2. **High Wear Resistance:** The hardness of SiC translates to high wear resistance, making it particularly effective in applications where friction and wear are significant factors. This is crucial in maintaining the integrity of mechanical seals over extended periods.

3. **Corrosion Resistance:** Silicon Carbide exhibits resistance to corrosion, making it suitable for applications involving aggressive or corrosive fluids. This resistance ensures the longevity of mechanical seal rings even in challenging chemical environments.

4. **Thermal Stability:** SiC has excellent thermal stability, allowing it to withstand high temperatures without compromising its structural integrity. This property is essential in applications where mechanical seals are exposed to elevated temperatures.

5. **Low Coefficient of Friction:** Silicon Carbide has a low coefficient of friction, contributing to reduced frictional heat generation and improved efficiency. This characteristic is beneficial in applications where minimizing heat and energy loss is critical.

6. **Chemical Inertness:** SiC is chemically inert, meaning it does not react with many chemicals. This inertness is advantageous in situations where the mechanical seal is exposed to various chemical substances, ensuring stability and reliability.

7. **High Strength:** Silicon Carbide possesses high strength, allowing mechanical seal rings to withstand substantial mechanical stress and pressure. This strength contributes to the overall robustness and reliability of the seal.

8. **Dimensional Stability:** Silicon Carbide exhibits good dimensional stability under varying conditions, ensuring that the mechanical seal maintains its shape and effectiveness over time. This is crucial for consistent performance in demanding applications.

9. **Reduced Maintenance:** The combination of hardness, wear resistance, and corrosion resistance results in reduced maintenance needs for equipment using Silicon Carbide Mechanical Seal Rings. This leads to cost savings and increased operational efficiency.

In summary, Silicon Carbide Mechanical Seal Rings offer a comprehensive set of advantages, making them ideal for demanding applications where durability, reliability, and performance are critical factors.

-

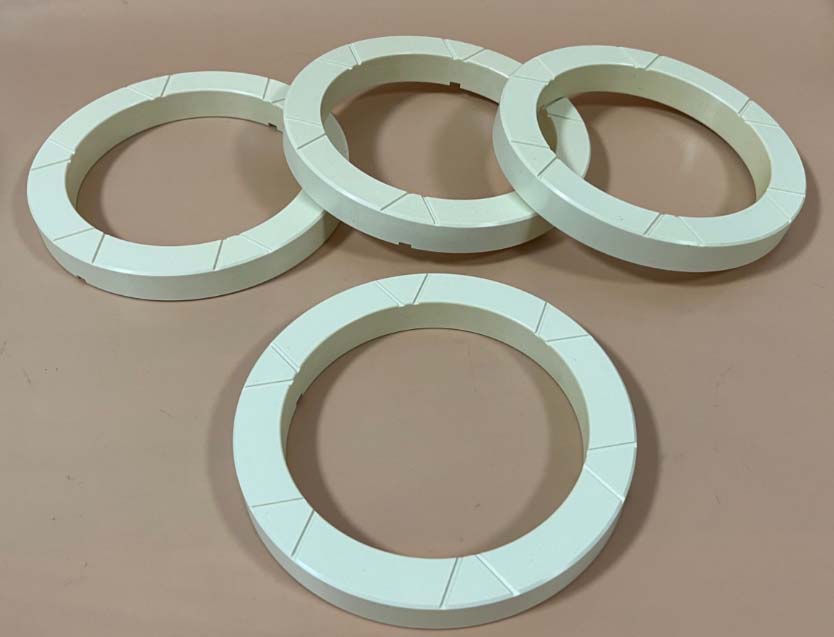

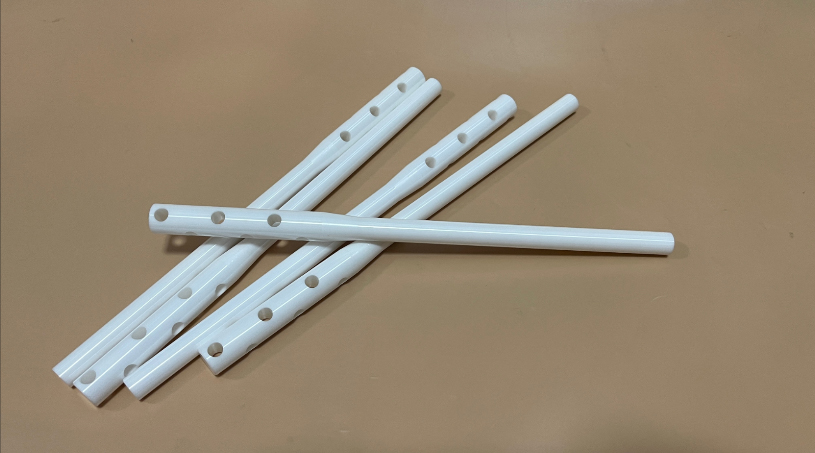

Silicon Carbide Mechanical Seal Rings

- Offer tribological performance under high load, including pressure, sliding speed, temperature.

- Provide excellent corrosion resistance and excellent thermal conductivity.

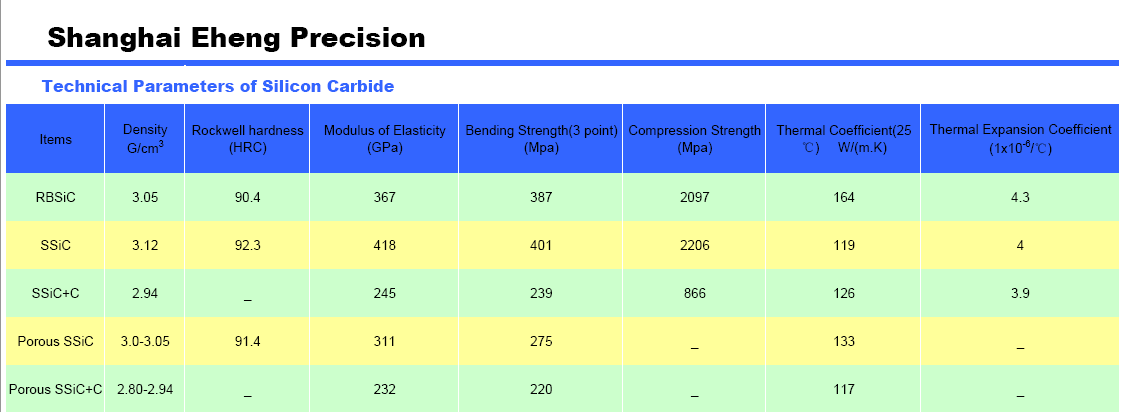

Shanghai Eheng Precision Technology Co.,LTD

Shanghai Eheng Precision Technology Co.,LTD