Enhanced Performance of Laboratory Attritors with Advanced Ceramic Components

In the realm of material science and industrial processing, laboratory Attritors have garnered significant attention for their efficiency and versatility in particle size reduction and dispersion. These high-energy ball mills, traditionally equipped with metallic components, have now been revolutionized with the introduction of advanced ceramic components. The incorporation of ceramic tanks, covers, shafts, arms, and grids made from Zirconium Oxide, Silicon Carbide, Tungsten carbide, Silicon nitride, and Aluminum Oxide has substantially enhanced the performance and application scope of laboratory Attritors.

Introduction to Laboratory Attritors

Laboratory Attritors, also known as stirred ball mills, are indispensable in research and development for achieving fine and uniform particle distributions. Their ability to deliver high-impact forces and efficient grinding mechanisms makes them ideal for producing nanoparticles, dispersing materials in suspensions, and conducting high-energy mechanical alloying. However, the performance of these devices is critically dependent on the materials used in their construction, especially when dealing with abrasive and corrosive substances.

Advancements in Ceramic Components

The integration of ceramic components into laboratory Attritors has marked a significant leap forward in addressing issues related to wear, contamination, and chemical compatibility. Each type of ceramic material brings distinct advantages to the table, enhancing the overall performance and longevity of the Attritors.

1. Zirconium Oxide (ZrO₂):

Zirconium Oxide, known for its high fracture toughness and resistance to wear and corrosion, is an ideal material for components exposed to severe mechanical stress. Its ability to withstand high temperatures and aggressive environments makes it suitable for tanks and shafts, ensuring consistent performance without degradation over time.

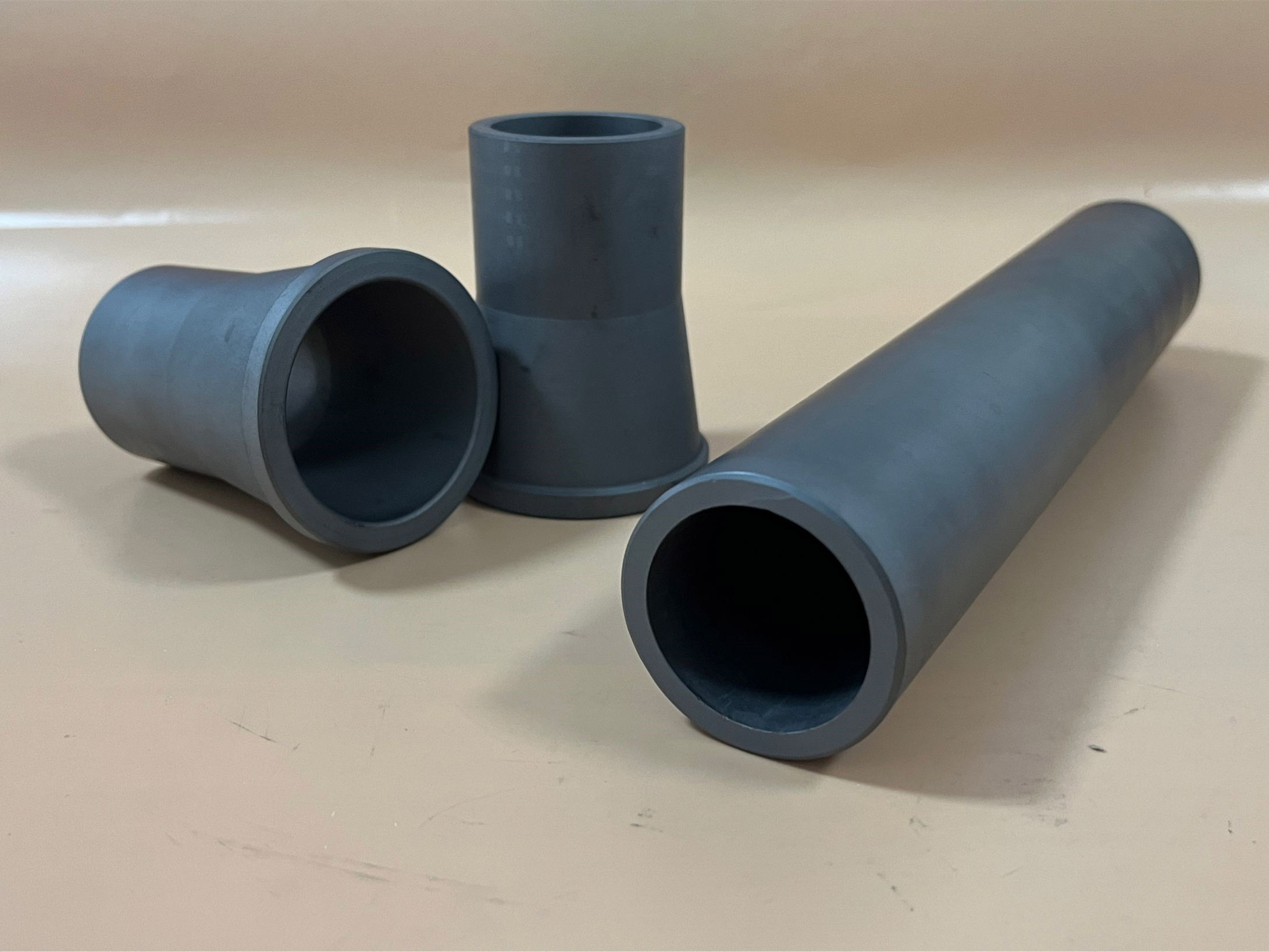

2. Silicon Carbide (SiC):

Silicon Carbide is renowned for its exceptional hardness and thermal conductivity. This makes it an excellent choice for covers and arms in Attritors, where thermal management and resistance to wear are critical. Its low density also contributes to a reduction in the overall weight of the equipment, enhancing operational efficiency.

3. Tungsten carbide (WC):

Tungsten Carbide offers unparalleled hardness and strength, making it a preferred material for components subjected to extreme grinding conditions. The incorporation of tungsten carbide grids and shafts ensures minimal wear and prolonged service life, even when processing highly abrasive materials.

4. Silicon nitride (Si₃N₄):

Silicon Nitride stands out for its high strength-to-weight ratio and excellent resistance to thermal shock and oxidation. This makes it an ideal choice for components like arms and covers that need to withstand rapid temperature changes and harsh operating conditions without compromising structural integrity.

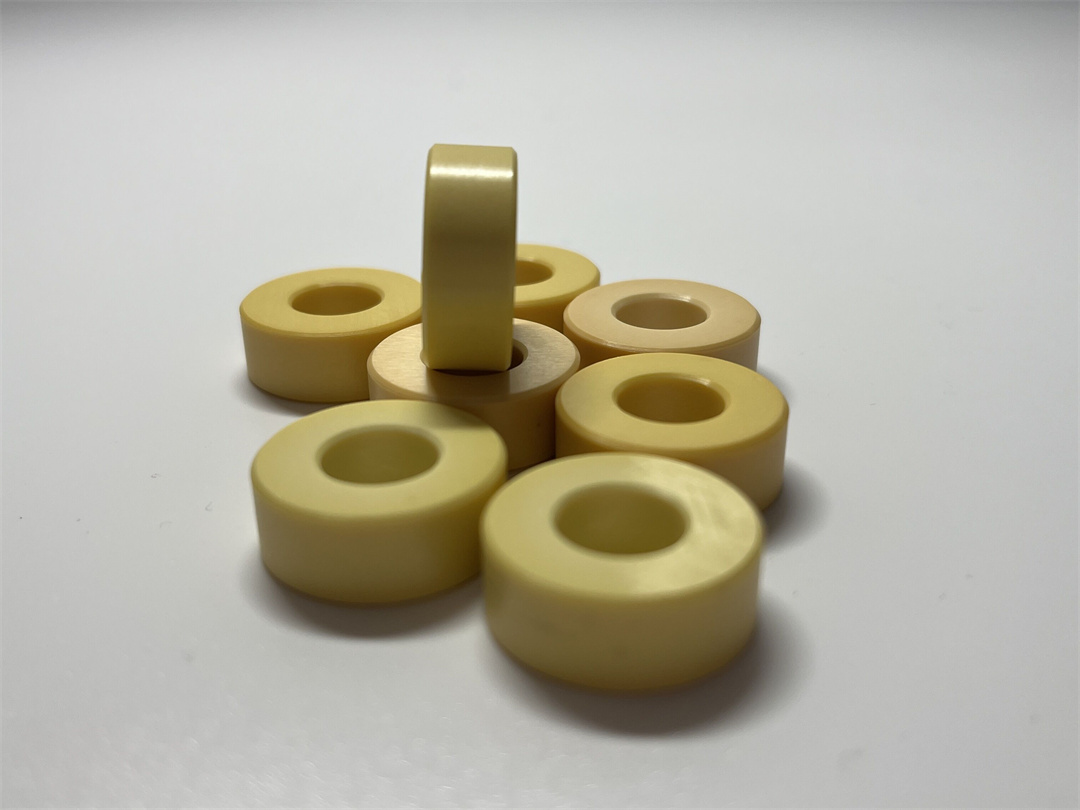

5. Aluminum Oxide (Al₂O₃):

Aluminum Oxide, or alumina, is valued for its high hardness, electrical insulation properties, and resistance to chemical attack. Its use in tanks and grids enhances the Attritor's capability to process a wide range of chemical compositions without contamination, maintaining the purity of the end products.

Performance Enhancement in Various Situations

The introduction of these advanced ceramic components has significantly broadened the application spectrum of laboratory Attritors. The improved wear resistance and chemical inertness of ceramic materials enable these Attritors to handle a diverse array of materials, from metallic powders and ceramics to polymers and pharmaceuticals. Additionally, the reduced contamination risk ensures the integrity and quality of sensitive products, making ceramic-enhanced Attritors indispensable in high-purity and high-precision applications.

Conclusion

The adoption of Zirconium Oxide, Silicon Carbide, Tungsten Carbide, Silicon Nitride, and Aluminum Oxide components in laboratory Attritors represents a transformative advancement in material processing technology. These ceramics provide unmatched durability, chemical resistance, and operational efficiency, making modern Attritors more reliable and versatile than ever before.As industries continue to demand higher performance and precision, the integration of advanced ceramics in laboratory Attritors will remain a cornerstone of innovation in material science and engineering.

Shanghai Eheng Precision Technology Co.,LTD

Shanghai Eheng Precision Technology Co.,LTD