Graphite-loaded sintered silicon carbide is a composite material used in various industrial applications, particularly in mechanical seals and other components subjected to high temperatures, pressure, and abrasive conditions. Here's a breakdown of its components and characteristics:

Graphite: Graphite is a form of carbon known for its lubricating properties and high thermal conductivity. It acts as a solid lubricant, reducing friction and wear between surfaces. In composite materials like graphite-loaded sintered silicon carbide, graphite is incorporated to enhance lubrication and reduce friction, improving the performance and longevity of the material.

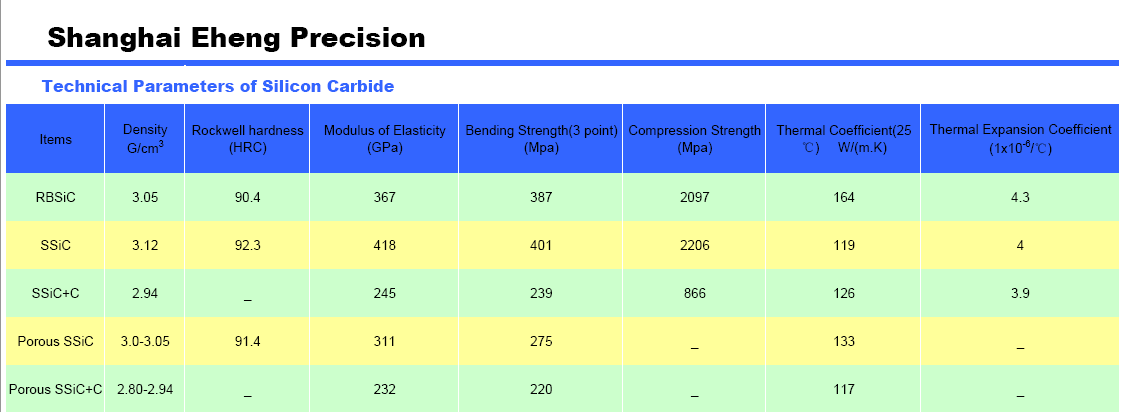

Sintered Silicon Carbide (SiC): Silicon carbide is a hard, non-metallic compound composed of silicon and carbon. It exhibits excellent mechanical properties, such as high hardness, abrasion resistance, and thermal conductivity. Sintered silicon carbide is produced by compacting silicon carbide powder and sintering it at high temperatures, resulting in a dense, durable material with superior mechanical and thermal properties.

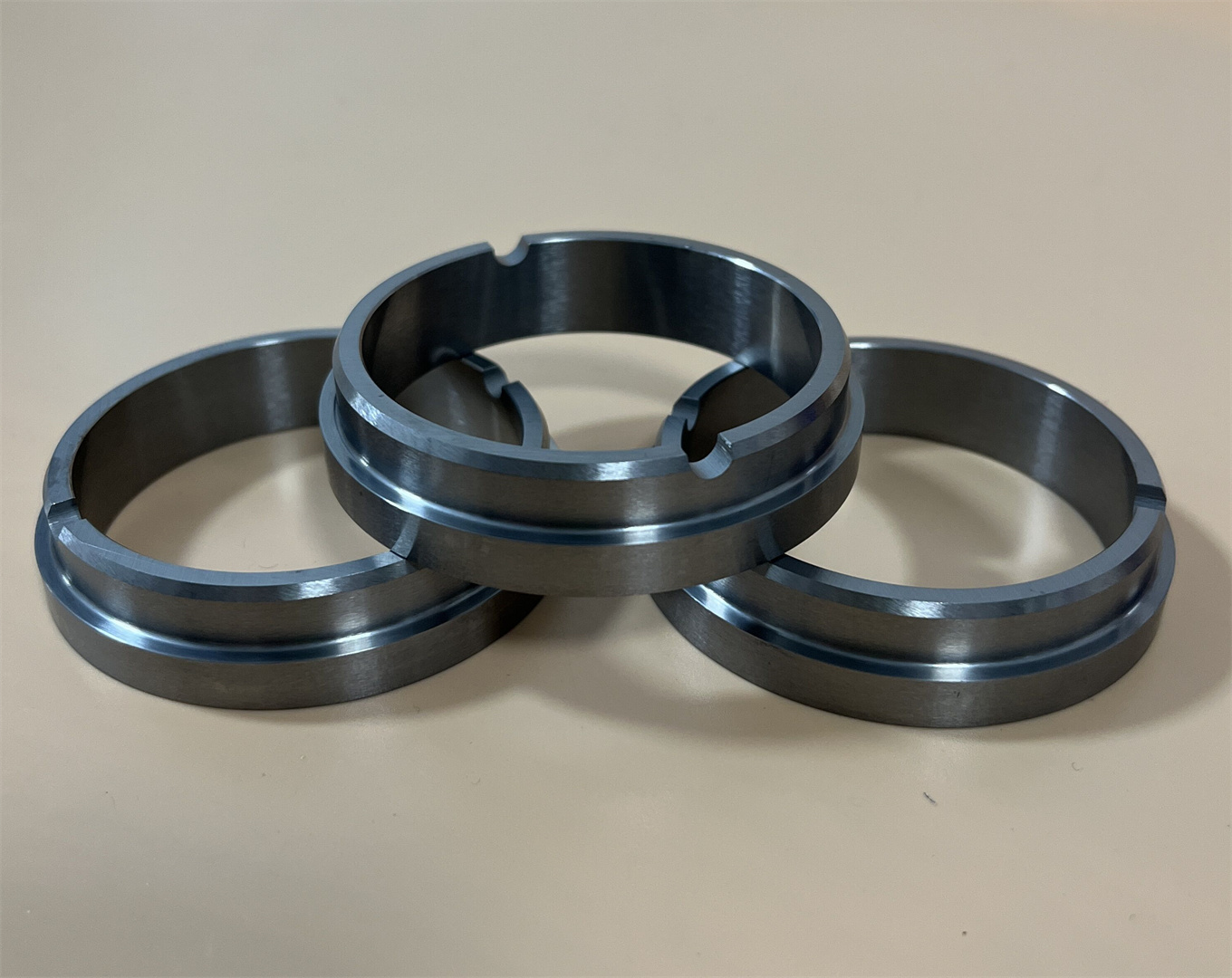

Composite Material: Graphite-loaded sintered silicon carbide combines the properties of graphite and sintered silicon carbide to create a material with enhanced lubrication, wear resistance, and thermal conductivity. Graphite particles are dispersed within the silicon carbide matrix, providing lubrication at the interface between mating surfaces. This composite material is well-suited for use in mechanical seals, bearings, and other components exposed to extreme conditions, where traditional materials may fail.

Applications: Graphite-loaded sintered silicon carbide is commonly used in mechanical seals for pumps, compressors, and other rotating equipment operating in challenging environments. It can withstand high temperatures, corrosive chemicals, and abrasive particles, making it ideal for applications in industries such as oil and gas, chemical processing, aerospace, and automotive manufacturing.

Overall, graphite-loaded sintered silicon carbide offers superior performance and reliability in demanding applications, thanks to its unique combination of properties derived from graphite and sintered silicon carbide.

Shanghai Eheng Precision Technology Co.,LTD

Shanghai Eheng Precision Technology Co.,LTD