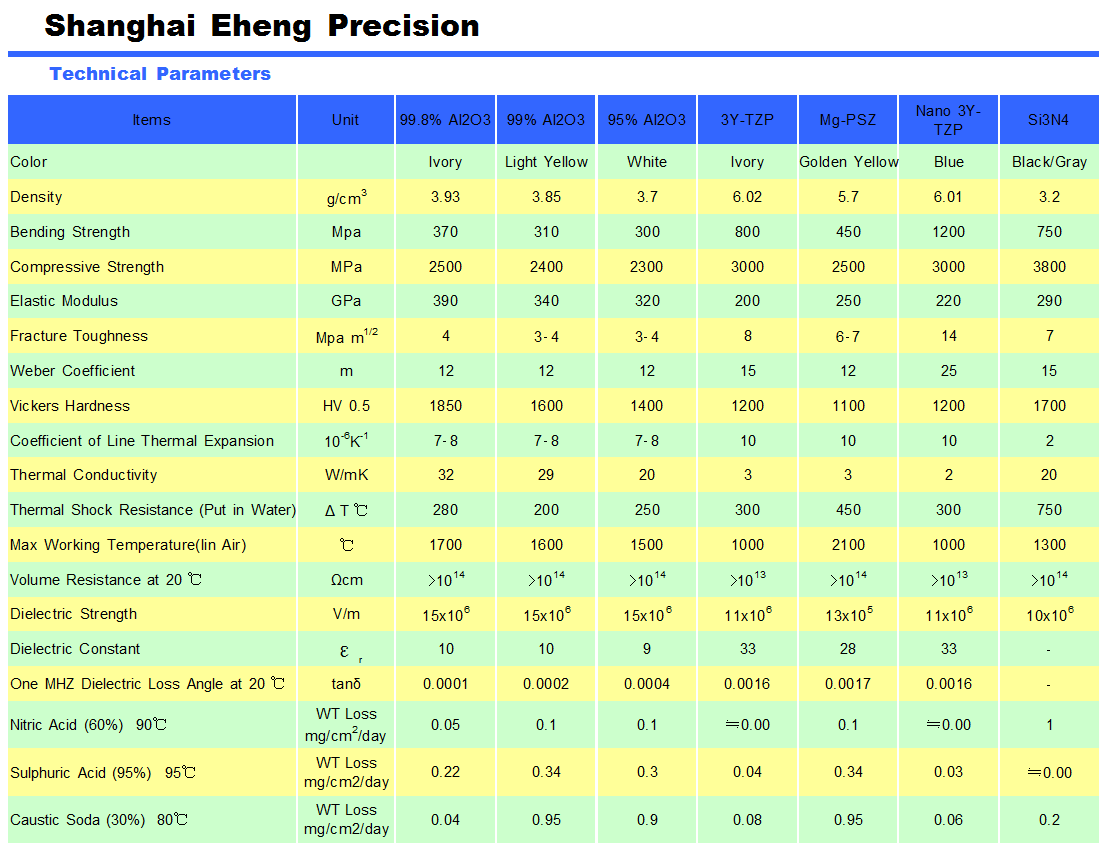

Silicon nitride valve and pump components are known for several key characteristics that make them suitable for demanding applications in various industries:

1. **High Hardness:**

- Silicon nitride exhibits high hardness, providing resistance to wear and abrasion. This makes it durable in applications where components are subjected to intense friction.

2. **Excellent Wear Resistance:**

- The material's wear resistance is crucial for prolonged performance in applications involving continuous movement and contact.

3. **High Temperature Stability:**

- Silicon nitride can withstand high temperatures, making it suitable for applications in environments with elevated temperatures.

4. **Low Thermal Expansion:**

- The material has a low coefficient of thermal expansion, contributing to its stability under temperature variations and reducing the risk of cracking.

5. **Corrosion Resistance:**

- Silicon nitride is resistant to many chemicals, providing excellent corrosion resistance. This is particularly important in applications where exposure to corrosive substances is a concern.

6. **Low Friction Coefficient:**

- Components made from silicon nitride often have a low friction coefficient, contributing to efficient operation and reduced energy consumption in moving parts.

7. **High Strength:**

- Silicon nitride is characterized by high strength, allowing for the design and manufacturing of components that can withstand mechanical stresses.

8. **Electrical Insulation:**

- Silicon nitride is an electrical insulator, making it suitable for applications where electrical conductivity is undesirable.

9. **Biocompatibility (for certain grades):**

- In some medical or bioengineering applications, specific grades of silicon nitride are biocompatible, making them suitable for use in medical implants or devices.

10. **Chemical Inertness:**

- Silicon nitride is chemically inert to many substances, ensuring stability and resistance to chemical reactions.

These characteristics collectively make silicon nitride a versatile material for valve and pump components in industries such as automotive, aerospace, chemical processing, and medical applications. Its combination of hardness, wear resistance, high-temperature stability, and other properties contributes to enhanced performance and durability in challenging environments.

For more details contact us freely.

Shanghai Eheng Precision Technology Co.,LTD

Shanghai Eheng Precision Technology Co.,LTD