-

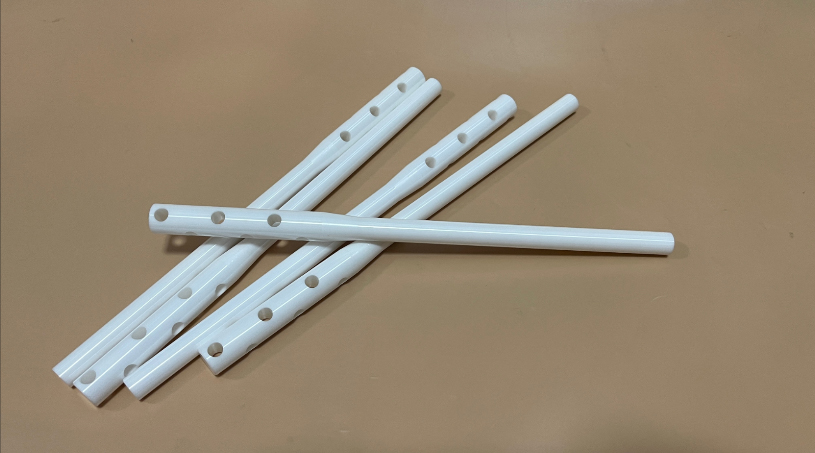

Carbon graphite seal rings: Enhancing Performance and Longevity in Industrial Applications

Introduction

Seal rings are pivotal components in a wide range of industrial machinery, ensuring the integrity and efficiency of fluid and gas containment systems. Among the various materials available for manufacturing seal rings, carbon graphite stands out due to its exceptional properties. This article explores the unique advantages of Carbon graphite seal rings, their applications, and the technological advancements they bring to industrial settings.

What is Carbon Graphite?

Carbon graphite is a composite material made from carbon and graphite, known for its high thermal conductivity, low coefficient of thermal expansion, and excellent self-lubricating properties. This combination of characteristics makes it an ideal material for seal rings used in demanding environments.

Properties of Carbon Graphite

1. Self-Lubrication: Carbon graphite has inherent lubricating properties, reducing the need for additional lubrication and minimizing friction between moving parts. This property is particularly valuable in applications where lubrication is challenging or impossible.

2. Thermal Conductivity: The high thermal conductivity of carbon graphite helps in dissipating heat effectively, preventing overheating and extending the lifespan of the seal ring.

3. Chemical Resistance: Carbon graphite is highly resistant to a wide range of chemicals, including acids, alkalis, and solvents, making it suitable for use in harsh chemical environments.

4. Low Thermal Expansion: The low coefficient of thermal expansion ensures that carbon graphite seal rings maintain their dimensional stability under temperature fluctuations, providing consistent sealing performance.

5. Wear Resistance: Carbon graphite is highly resistant to wear and abrasion, which is critical for maintaining the integrity and performance of the seal over time.

-

Applications of Carbon Graphite Seal Rings

Carbon graphite seal rings are utilized across various industries, including:

1. Aerospace: In aircraft engines and other aerospace applications, carbon graphite seal rings provide reliable sealing in extreme temperature and pressure conditions, ensuring the safe and efficient operation of critical systems.

2. Automotive: These seal rings are used in automotive engines, pumps, and transmissions to maintain fluid and gas integrity, contributing to the overall performance and efficiency of the vehicle.

3. Chemical Processing: The chemical resistance of carbon graphite makes it ideal for use in pumps, compressors, and other equipment handling aggressive chemicals, ensuring long-lasting and reliable sealing.

4. Power Generation: In power plants, carbon graphite seal rings are used in turbines, compressors, and other high-temperature equipment to maintain effective sealing under demanding conditions.

5. Oil & Gas: The durability and resistance to wear and corrosion make carbon graphite seal rings suitable for use in oil and gas extraction and processing equipment, where they encounter abrasive and corrosive environments.

Advantages Over Traditional Materials

Compared to traditional sealing materials like metals and elastomers, carbon graphite offers several distinct advantages:

- Enhanced Durability: The wear resistance and self-lubricating properties of carbon graphite lead to longer service life and reduced maintenance requirements.

- Improved Performance: The ability to maintain effective sealing under extreme temperatures and chemical exposures ensures optimal performance in critical applications.

- Cost Efficiency: The longevity and reliability of carbon graphite seal rings translate into lower replacement costs and less downtime, providing economic benefits over time.

Technological Advancements

Recent advancements in manufacturing and material science have further enhanced the performance of carbon graphite seal rings. Innovations include:

- Composite Materials: Development of carbon graphite composites with enhanced properties tailored for specific applications, such as increased wear resistance or improved thermal stability.

- Precision Manufacturing: Advances in precision manufacturing techniques have enabled the production of seal rings with tighter tolerances and more complex geometries, improving sealing performance and reliability.

-Surface Treatments: Application of surface treatments and coatings to carbon graphite seal rings can further enhance their properties, such as reducing friction or increasing chemical resistance.

Conclusion

Carbon graphite seal rings represent a significant advancement in sealing technology, offering unparalleled performance in a variety of demanding industrial applications. Their unique combination of self-lubrication, thermal conductivity, chemical resistance, and wear resistance makes them an invaluable component in ensuring the reliability and efficiency of modern machinery. As industries continue to seek higher performance and longer-lasting solutions, carbon graphite seal rings are poised to play an increasingly vital role in the future of industrial sealing technology.

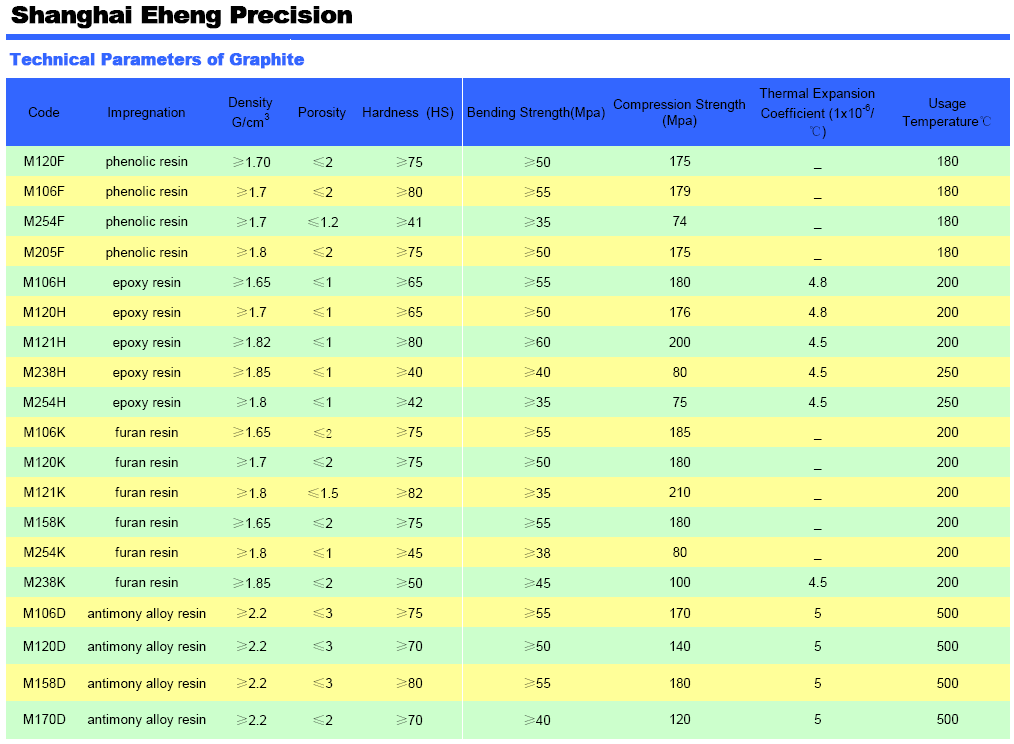

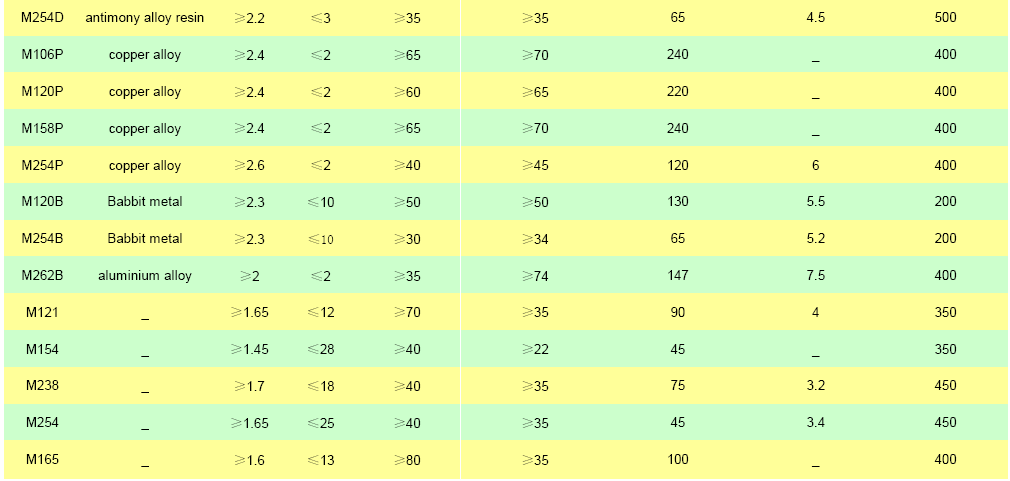

Technical parameters

For more details,contact us freely.

Shanghai Eheng Precision Technology Co.,LTD

Shanghai Eheng Precision Technology Co.,LTD