A zirconia impact ring is a component typically used in various industrial applications due to its exceptional mechanical properties, including high strength, toughness, and resistance to wear and corrosion. Zirconia, also known as zirconium dioxide (ZrO2), is a type of advanced ceramic material renowned for its high fracture toughness and excellent thermal and chemical stability. Here’s a detailed look at the properties and applications of zirconia impact rings:

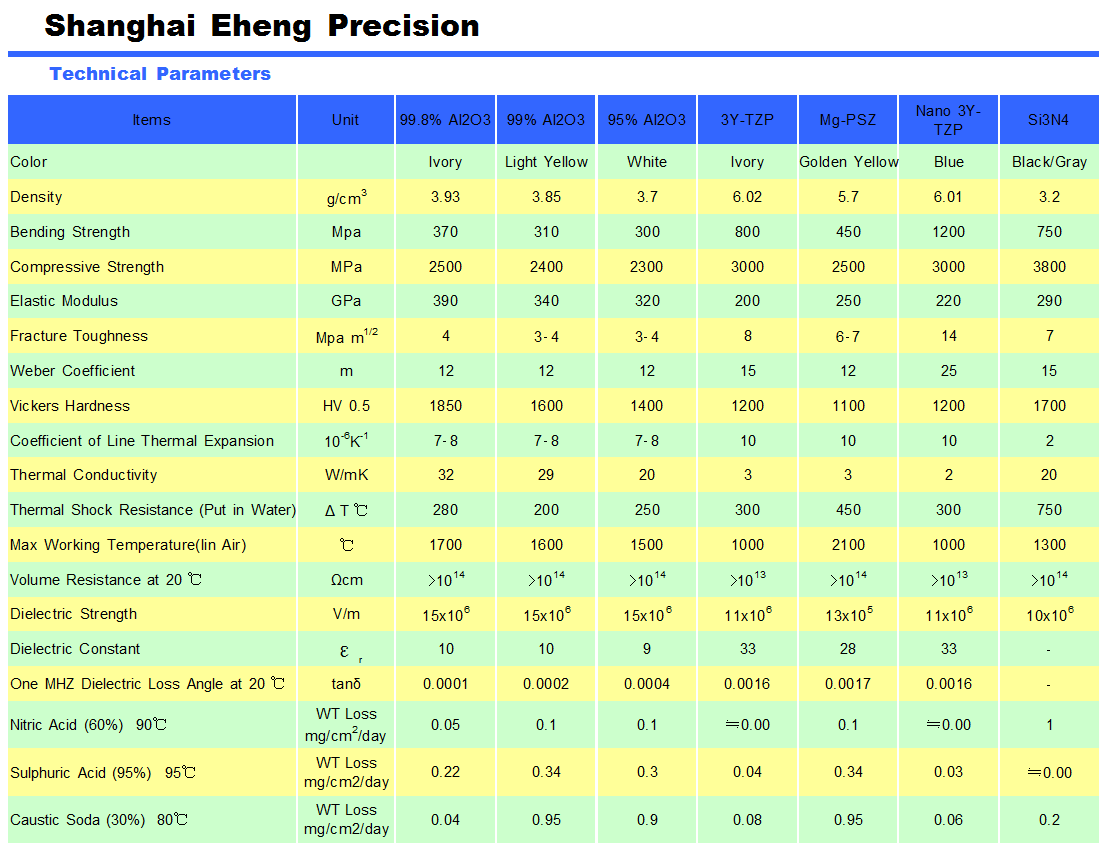

High Toughness and Strength: Zirconia ceramics are known for their high fracture toughness, which is significantly higher than that of other ceramics. This makes them highly resistant to cracking and fracture under mechanical stress.

Wear Resistance: Due to their hardness, zirconia ceramics exhibit excellent wear resistance, making them suitable for applications where the component is subject to constant friction or abrasion.

Thermal Stability: Zirconia can withstand high temperatures without degrading, making it ideal for use in high-temperature environments.

Chemical Inertness: Zirconia is resistant to chemical corrosion and does not react with most acids and alkalis, making it suitable for use in chemically harsh environments.

Low Thermal Conductivity: Unlike many other ceramics, zirconia has a relatively low thermal conductivity, which allows it to retain heat longer and provides thermal insulation properties.

Electrical Insulation: Zirconia is also an excellent electrical insulator, making it useful in electronic and electrical applications.

Mechanical Seals and Bearings: Due to their toughness and wear resistance, zirconia impact rings are often used in mechanical seals and bearings where they can withstand significant mechanical stress and friction.

Cutting Tools: The hardness and durability of zirconia make it suitable for cutting tools and wear-resistant parts.

Aerospace and Automotive Industries: Zirconia impact rings are used in high-stress environments within the aerospace and automotive industries due to their ability to withstand extreme conditions.

Medical Implants: Zirconia is biocompatible and is used in dental and orthopedic implants. The impact rings in medical devices benefit from zirconia’s strength and resistance to wear and corrosion.

Thermal Insulation Components: Given their low thermal conductivity, zirconia impact rings are used in applications requiring thermal insulation, such as in furnaces and kilns.

Electronics: Zirconia’s electrical insulation properties make it useful in various electronic components.

Zirconia impact rings are critical components in many industrial applications due to their superior mechanical properties, including high strength, toughness, and resistance to wear and corrosion. Their ability to perform under extreme conditions makes them invaluable in industries ranging from aerospace and automotive to medical and electronics. The versatility and reliability of zirconia as a material ensure its continued importance in advancing technology and engineering solutions.

Properties of Zirconia

Applications of Zirconia Impact Rings

Conclusion

Shanghai Eheng Precision Technology Co.,LTD

Shanghai Eheng Precision Technology Co.,LTD