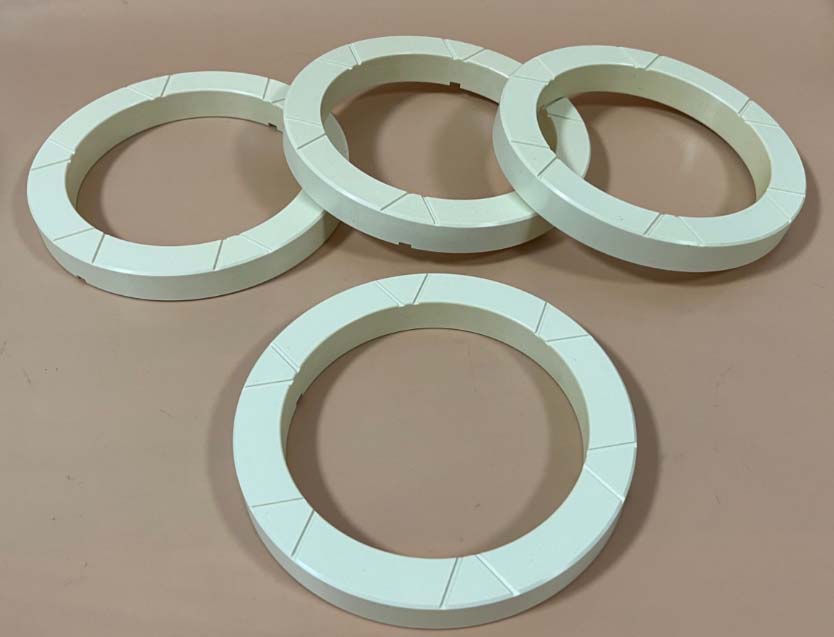

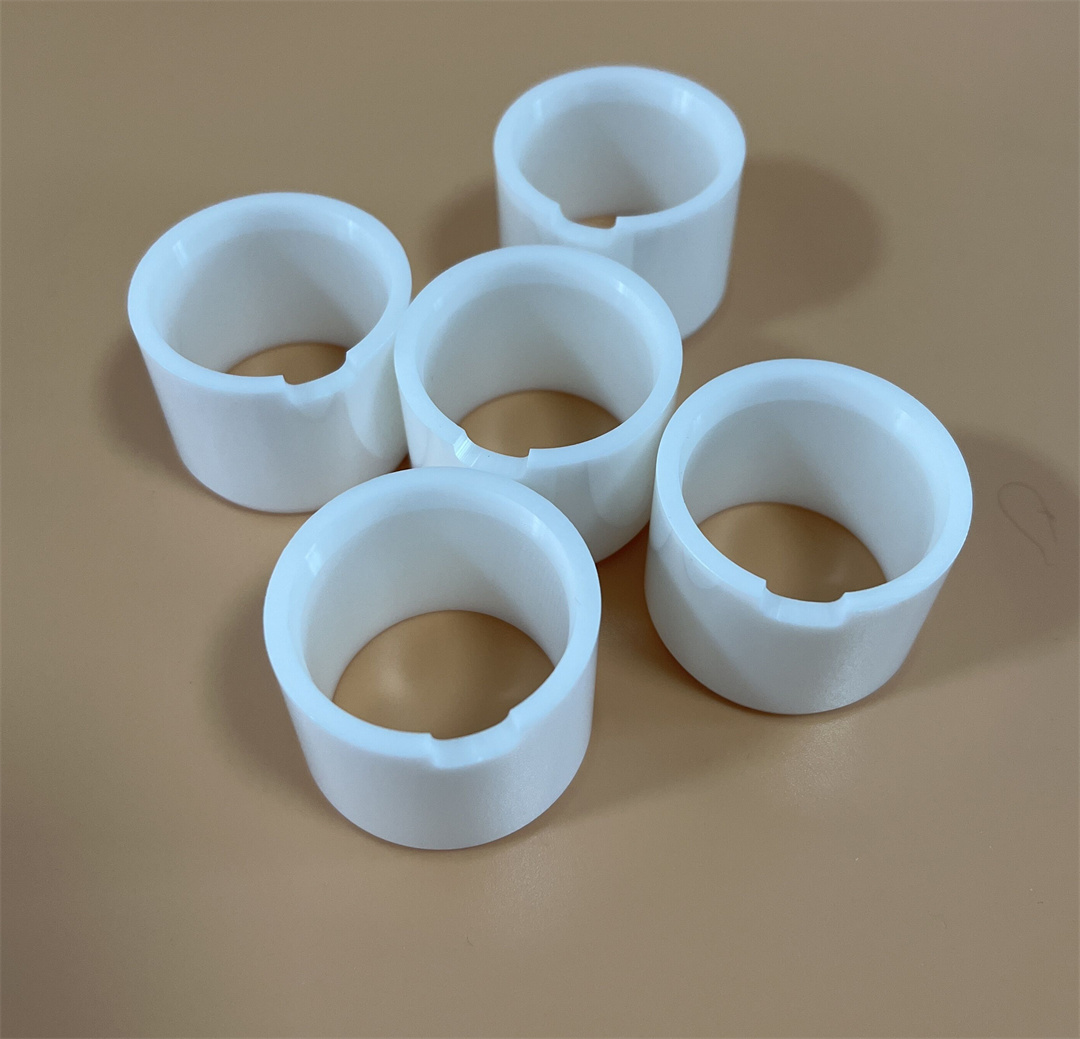

Alumina ceramic elbow liners offer several key characteristics that make them suitable for applications where wear resistance and durability are crucial. Here are the main features of alumina ceramic elbow liners:

1. **High Hardness:**

- Alumina ceramic is known for its high hardness, providing excellent resistance to wear and abrasion. This property contributes to the extended lifespan of elbow liners.

2. **Wear Resistance:**

- Alumina ceramic elbow liners exhibit exceptional wear resistance, making them suitable for applications involving continuous flow of abrasive materials.

3. **High Temperature Stability:**

- Alumina ceramic can withstand high temperatures without significant degradation, making it suitable for use in applications with elevated temperatures.

4. **Chemical Inertness:**

- Alumina ceramic is chemically inert to many substances, providing resistance to corrosion. This characteristic is crucial in applications where exposure to corrosive materials is common.

5. **Dimensional Stability:**

- Alumina ceramic maintains its dimensional stability under various conditions, ensuring consistent performance and preventing deformation or distortion of elbow liners.

6. **Electrical Insulation:**

- Alumina ceramic is an electrical insulator, preventing the flow of electrical currents. This property is important in applications where electrical conductivity is undesirable.

7. **Lightweight:**

- Alumina ceramic elbow liners are lightweight, making them suitable for applications where reducing overall weight is important.

8. **Versatility in Applications:**

- Alumina ceramic elbow liners can be used in various applications, including pneumatic and hydraulic conveying systems, chutes, and other industrial processes where wear resistance is critical.

9. **Corrosion Resistance:**

- Alumina ceramic provides resistance to corrosion, enhancing its suitability for elbow liners used in environments where exposure to corrosive materials is a concern.

10. **Smooth Surface Finish:**

- Alumina ceramic elbow liners can be engineered to have a smooth surface finish, reducing friction and improving material flow through the system.

11. **Biocompatibility (for certain grades):**

- In some medical or bioengineering applications, specific grades of Alumina Ceramics are biocompatible, making them suitable for use in medical implants or devices.

These characteristics collectively make alumina ceramic elbow liners valuable in industries such as mining, cement, power generation, and others where reliable and durable components are essential for efficient material handling and flow processes.

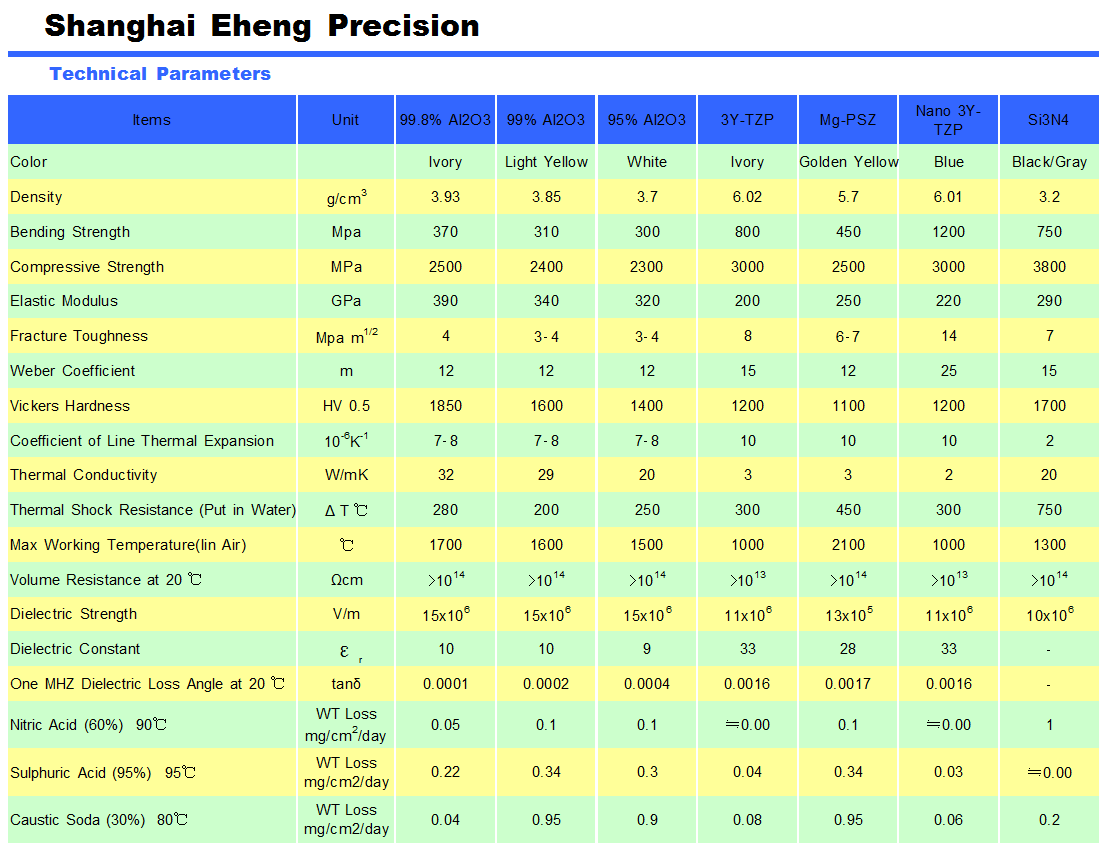

We offer ceramic parts made of alumina with the purity from 95% and 99.8% (NON-POROUS). High purity Alumina Ceramics are particularly suitable for applications where the working enviroments have very strict requirment about abrasion or corrosion resistance. And due to its excellent thermal stability (stable chemical properties and low thermal expansion), alumina ceramics can be used in an environment that temperature drastic changes.

Shanghai Eheng Precision Technology Co.,LTD

Shanghai Eheng Precision Technology Co.,LTD