Porous graphite-loaded sintered silicon carbide (PG-SSiC) is a specialized composite material used in various high-performance applications, particularly in industries such as aerospace, automotive, and chemical processing. This material combines the properties of porous graphite and sintered silicon carbide to create a unique material with specific characteristics. Here's a breakdown of its components and characteristics:

-

Porous Graphite: Porous graphite is a form of graphite that contains voids or pores within its structure. These pores can be engineered to achieve specific porosity levels and pore size distributions. Porous graphite offers advantages such as high thermal conductivity, low density, and excellent corrosion resistance. It is often used in applications where lightweight, heat transfer, and chemical resistance are critical.

-

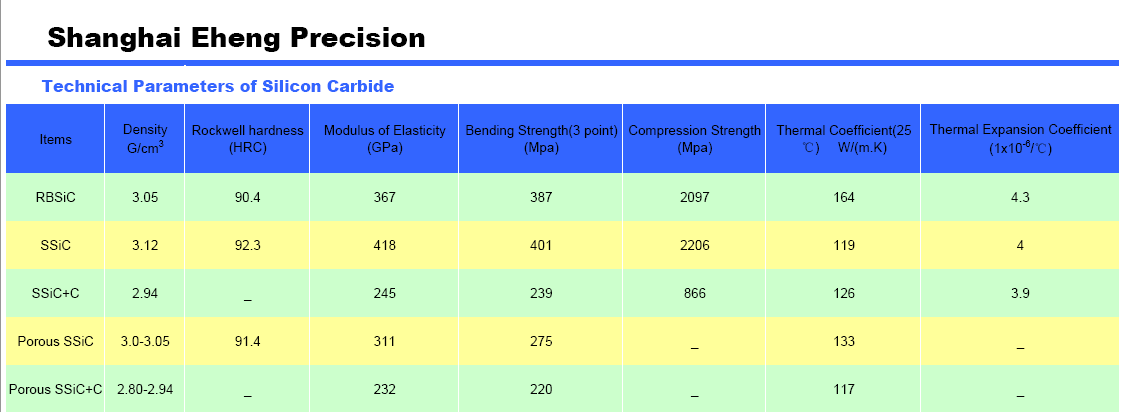

Sintered Silicon Carbide (SSiC): Sintered silicon carbide is a hard and durable ceramic material known for its exceptional mechanical properties, including high hardness, wear resistance, and thermal conductivity. It is produced by sintering silicon carbide powder at high temperatures, resulting in a dense and strong material suitable for harsh environments.

-

Composite Material: Porous graphite-loaded sintered silicon carbide combines the properties of porous graphite and sintered silicon carbide. The porous graphite phase provides enhanced thermal conductivity and reduced density, while the sintered silicon carbide phase offers superior mechanical strength and wear resistance. By incorporating graphite into the silicon carbide matrix, the material gains benefits such as improved lubrication and thermal management.

-

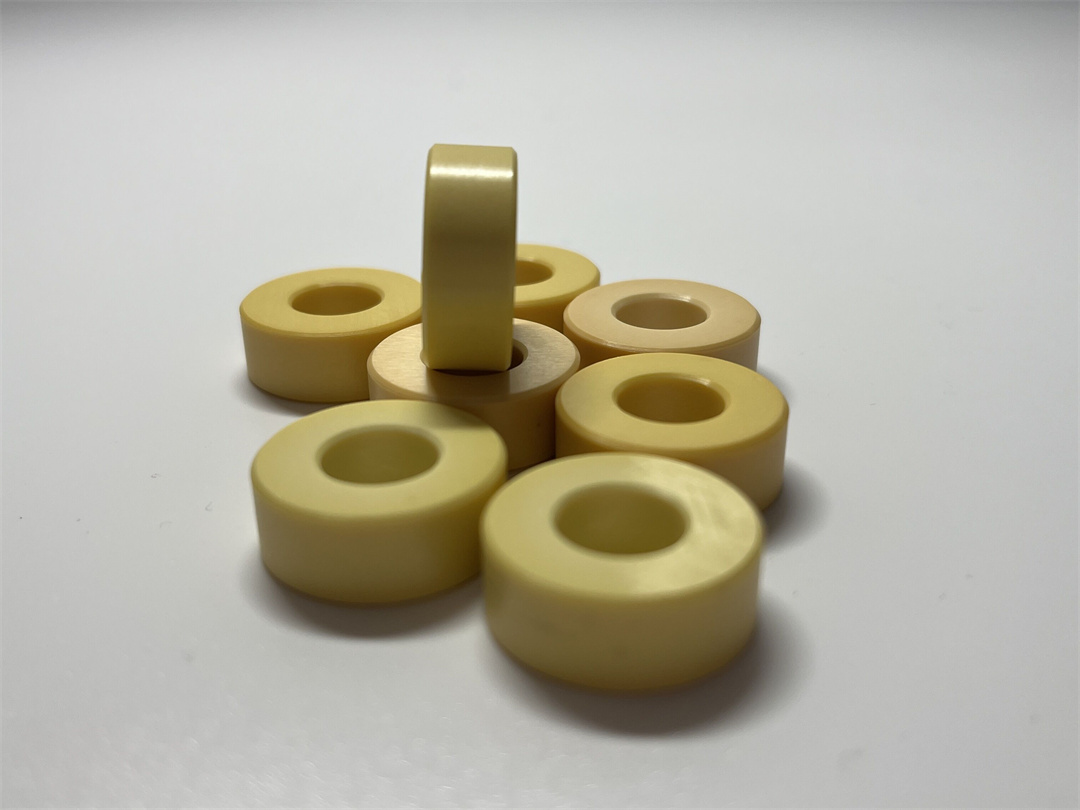

Applications: PG-SSiC finds applications in various industries where a combination of lightweight, high strength, thermal conductivity, and chemical resistance is required. Common applications include components for aerospace propulsion systems, automotive brake systems, heat exchangers, and chemical processing equipment. PG-SSiC seals, bearings, and bushings are also used in high-temperature and high-pressure environments where conventional materials may fail.

Overall, porous graphite-loaded sintered silicon carbide offers a unique combination of properties tailored to specific engineering requirements, making it an attractive choice for demanding applications in harsh operating conditions.

Shanghai Eheng Precision Technology Co.,LTD

Shanghai Eheng Precision Technology Co.,LTD