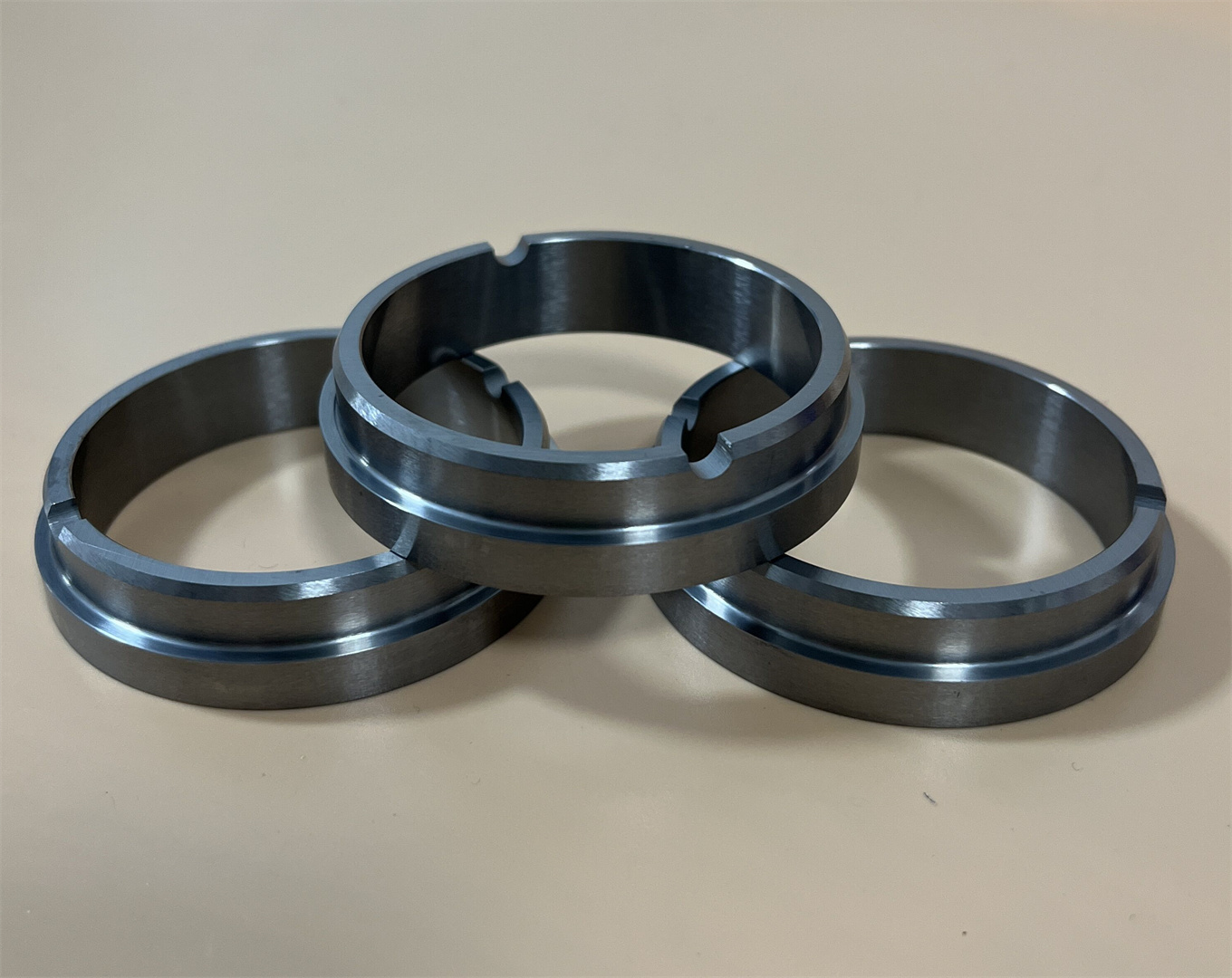

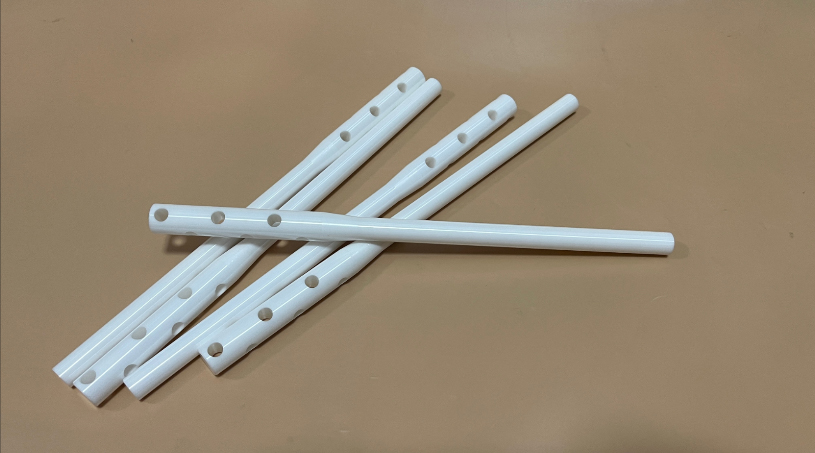

Silicon carbide (SiC) pump sleeves, bushings, bushes, or shaft sleeves are are widely used in the magnetic pumps, shield pumps, multistage pumps, hydraulic pumps, chemical pumps, centrifuges and so on for ceramic has a low friction and a good resistance to wear

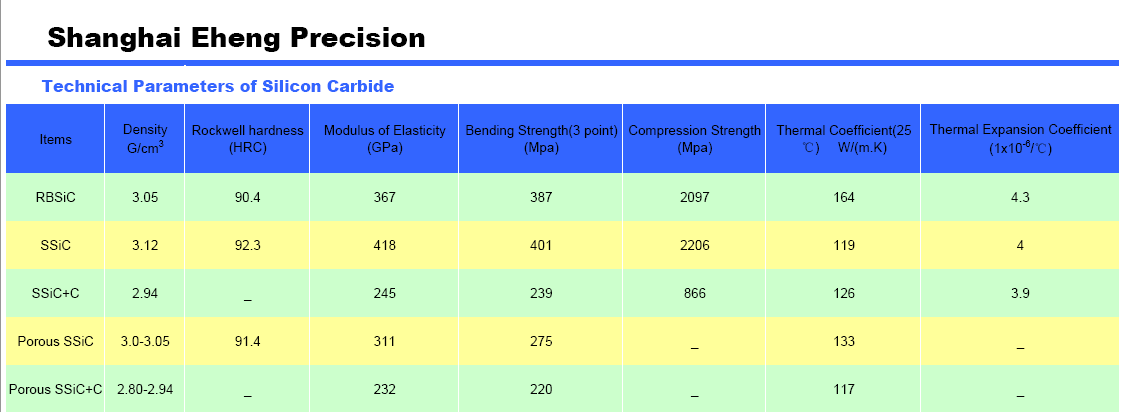

Silicon carbide, known for its hardness, thermal conductivity, and resistance to wear, corrosion, and thermal shock, makes it an ideal material for challenging operating conditions.

Here are some of the key applications and advantages of using SiC in these components:

Applications

1. Chemical Processing Industry:

- SiC is chemically resistant to nearly all acids, alkalis, and solvents, making it suitable for pumps transporting aggressive chemicals.

2. Oil and Gas Industry:

- Used in pumps that handle crude oil, water, and other fluids at high temperatures and pressures. SiC's thermal stability and resistance to abrasion and corrosion make it ideal for such environments.

3. Water Treatment and Desalination Plants:

- SiC sleeves are used in pumps that move seawater or chemically treated water, benefiting from SiC's resistance to erosion and corrosion.

4. Mining and Slurry Pumps:

- The hardness and wear resistance of SiC make it suitable for pumps that transport abrasive slurries in the mining sector.

5. Power Generation:

- In power plants, SiC components are used in pumps handling various fluids, including boiler feed water, benefiting from their thermal stability and wear resistance.

6. Semiconductor Manufacturing:

- SiC is used in ultra-pure water pumps and chemical delivery systems in the semiconductor manufacturing process, where chemical inertness and purity are critical.

Advantages

Wear Resistance:SiC's extreme hardness (next to diamonds) ensures prolonged life in abrasive environments, reducing downtime and maintenance costs.

Corrosion Resistance: Its chemical inertness allows SiC to stand up to corrosive substances, expanding the range of fluids that can be safely pumped.

Thermal Stability: SiC maintains its strength at high temperatures, making it suitable for hot fluids and environments where thermal shocks are common.

Mechanical Strength: SiC components can withstand high pressures and harsh mechanical conditions.

Reduced Friction: SiC has a low coefficient of friction when matched with suitable materials, leading to reduced energy consumption and heat generation in pumps.

Overall, the use of silicon carbide in pump sleeves, bushings, or shaft sleeves improves the efficiency, reliability, and longevity of pumping systems, particularly in industries where harsh conditions are the norm.

For more details,contact us freely.

Shanghai Eheng Precision Technology Co.,LTD

Shanghai Eheng Precision Technology Co.,LTD