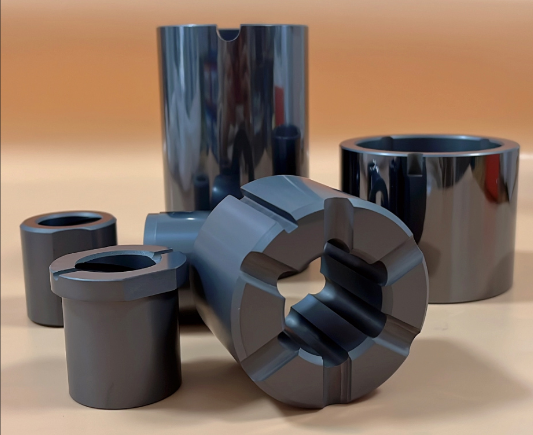

Ceramic Bushings/Sleeves and Shafts: Advanced Materials for High-Performance Applications

Ceramic bushings, sleeves, and shafts are essential components in many industrial applications, offering superior performance due to their unique properties. Materials such as silicon carbide (SiC), sintered silicon carbide (SSiC), Tungsten carbide (TC), aluminium oxide (ceramic 99% and 99.5%), carbon/graphite, and zirconia are widely used in the production of these components.

1. Silicon Carbide (SiC) and Sintered Silicon Carbide (SSiC)

Silicon carbide and its sintered form, SSiC, are renowned for their exceptional hardness, thermal conductivity, and resistance to wear and corrosion. These materials are ideal for applications where high performance and durability are required.

- Applications: SiC and SSiC bushings, sleeves, and shafts are commonly used in magnetic pumps, shield pumps, multistage pumps, hydraulic pumps, and chemical pumps. Their high thermal stability and resistance to chemical attack make them suitable for harsh environments.

Silicon Carbide sleeves

2. Tungsten carbide (TC)

Tungsten carbide is another material known for its incredible hardness and wear resistance. It also exhibits good thermal conductivity and is highly resistant to abrasion and corrosion.

- Applications: TC bushings and shafts are used in applications where extreme wear resistance is crucial, such as in centrifuges and heavy-duty pumps. The durability of tungsten carbide ensures long service life even in the most demanding conditions.

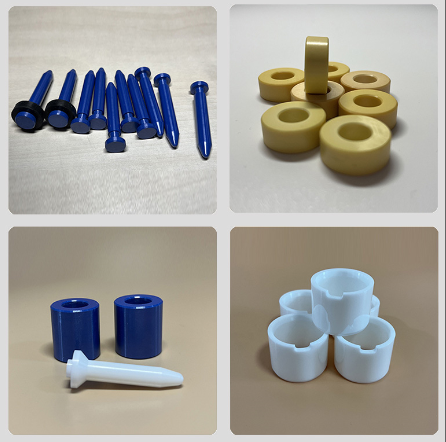

Tungsten carbide seal faces

3. Aluminium Oxide (Ceramic 99% and 99.5%)

Aluminium oxide, available in 99% and 99.5% purity, is a ceramic material that offers excellent electrical insulation, high thermal conductivity, and exceptional resistance to wear and corrosion.

- Applications: Bushings, sleeves, and shafts made from aluminium oxide are used in magnetic pumps, shield pumps, and various types of chemical and hydraulic pumps. The material's low friction and good wear resistance enhance the efficiency and longevity of these components.

Alumina seal faces

4. Carbon/Graphite

Carbon and graphite are known for their self-lubricating properties, low friction, and good resistance to thermal shock and chemical attack. These materials are particularly useful in applications where lubrication is critical.

- Applications: Carbon/graphite bushings and shafts are widely used in pumps and machinery where low friction and good wear resistance are essential. They are commonly found in magnetic pumps, shield pumps, and chemical pumps.

Carbon graphite seal ring

5. Zirconia

Zirconia is a ceramic material that stands out for its high strength, toughness, and excellent resistance to wear and corrosion. It also has good thermal stability and low thermal conductivity.

- Applications: zirconia bushings and shafts are used in high-performance applications such as multistage pumps, hydraulic pumps, and centrifuges. The material's robust properties ensure reliable performance in demanding environments.

zirconia bushings

6. Benefits of Ceramic Materials

Ceramic materials, including silicon carbide, aluminium oxide, and zirconia, offer several key benefits that make them suitable for use in bushings, sleeves, and shafts:

- Low Friction: Ceramics have inherently low friction, which reduces wear and improves the efficiency of moving parts.

- High Wear Resistance: The hardness and durability of ceramic materials ensure long service life and reduced maintenance.

- Chemical Resistance: Ceramics are resistant to a wide range of chemicals, making them ideal for use in corrosive environments.

- Thermal Stability: Ceramics can withstand high temperatures without degrading, ensuring consistent performance in thermal-intensive applications.

Ceramic bushings, sleeves, and shafts made from silicon carbide, aluminium oxide, tungsten carbide, carbon/graphite, and zirconia are critical components in various industrial applications. Their unique properties, such as low friction, high wear resistance, and excellent chemical and thermal stability, make them indispensable in pumps and machinery used in the chemical, hydraulic, and power generation industries. By leveraging the advantages of these advanced materials, industries can achieve greater efficiency, reliability, and longevity in their operations.

If you need further details or specific customization, feel free to let us know!

Shanghai Eheng Precision Technology Co.,LTD

Shanghai Eheng Precision Technology Co.,LTD