Mechanical seal rings or faces are crucial components of end-face mechanical seals, designed to ensure efficient sealing and long-lasting performance in various industrial applications. These rings or faces serve as the axially flexible members of the seal, playing a vital role in minimizing distortion, maximizing heat transfer, and accommodating secondary sealing elements, drive mechanisms, springs, and ease of assembly. This article explores the design, materials, and distinct characteristics of mechanical seal rings or faces.

1. The Role of Mechanical Seal Rings or Faces

The primary function of the mechanical seal ring or face is to provide a reliable seal between rotating and stationary components, preventing fluid leakage. The design must ensure:

Minimized Distortion: The mechanical seal ring must maintain its shape under pressure to ensure an effective seal.

Maximized Heat Transfer: Efficient heat dissipation is crucial to prevent overheating and maintain seal integrity.

Secondary Sealing Element Accommodation: The design must integrate secondary sealing elements to enhance overall sealing performance.

Drive Mechanism Integration: Ensuring proper engagement with the drive mechanism is essential for the seal's operation.

Ease of Assembly: The mechanical seal ring must be easy to assemble and disassemble for maintenance and replacement.

2. Materials Used in Mechanical Seal Rings or Faces

Mechanical seal rings or faces are made from a variety of materials, each selected for its specific properties and suitability for different applications. The most common materials include:

Pressureless Sintered Silicon Carbide/Alpha Silicon Carbide/Alpha SiC/SSiC: Known for its exceptional hardness, thermal conductivity, and resistance to wear and corrosion.

Silicon Carbide (SiC): Offers excellent thermal stability and chemical resistance.

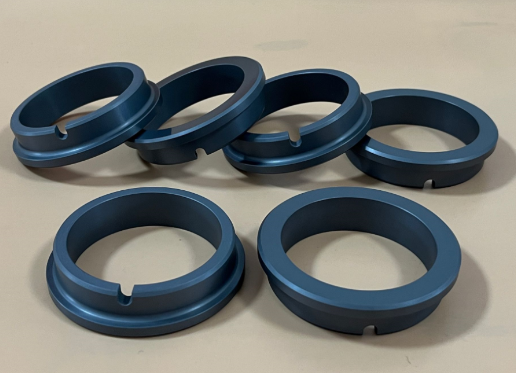

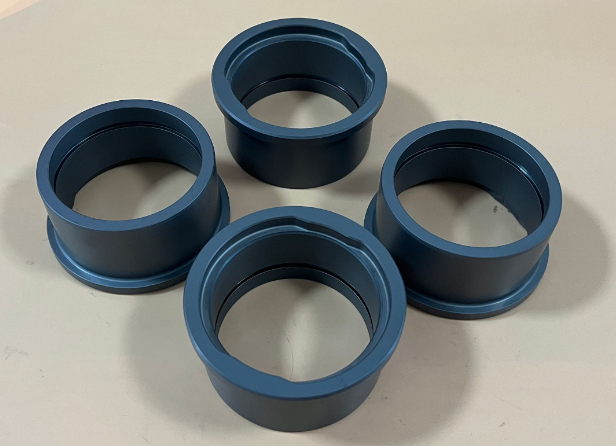

Sic mechanical seal rings or faces

SSic mechanical seal rings or faces

Ceramic (99.5%, 99%, 95%): Provides good wear resistance, electrical insulation, and chemical stability.

alumina ceramic mechanical seal rings or faces

Tungsten carbide (TC): Renowned for its high hardness, wear resistance, and toughness.

Tungsten carbiden mechanical seal rings or faces

Carbon Graphite: Features low friction, good wear resistance, and self-lubricating properties.

Carbon mechanical seal rings or faces

Chrome Coated Stainless Steel: Sometimes used to enhance the wear resistance and corrosion resistance of stainless steel seal faces.

Mechanical seal rings or faces always incorporate diameter balance. This balance is essential for distributing pressure evenly across the seal faces, reducing wear and extending the seal's lifespan. Proper diameter balance ensures that the seal can handle varying pressures and maintain effective sealing under different operational conditions.

4. Design Variations

The shape of mechanical seal rings or faces can vary significantly based on the incorporation of various design features. These design variations are often the most distinct identifying characteristics of mechanical seals. Factors influencing the shape include:

Application Requirements: Different industries and applications require specific seal designs to meet their unique needs.

Material Properties: The chosen material's properties can influence the ring's shape and overall design.

Operational Conditions: The seal's design must accommodate the operational environment, including temperature, pressure, and chemical exposure.

Mechanical seal rings or faces are vital components that ensure the reliability and efficiency of mechanical seals in various industrial applications. Their design must balance multiple factors, including minimizing distortion, maximizing heat transfer, and accommodating secondary sealing elements. The choice of material and the shape of the seal rings or faces play critical roles in their performance and longevity. By understanding the unique properties and applications of different materials, industries can select the most suitable mechanical seal rings or faces for their specific needs, ensuring optimal performance and durability.

If you need further details or specific customization, feel free to contact us

Shanghai Eheng Precision Technology Co.,LTD

Shanghai Eheng Precision Technology Co.,LTD