Silicon carbide (SiC) is a significant ceramic material known for its high hardness, thermal conductivity, high-temperature stability, and corrosion resistance.

Depending on its manufacturing method and application, silicon carbide products can be categorized into various types and applications:

1.Reaction bonded silicon carbide

Usually it appears as SiC,RBSIC,SiSiC or Q2.

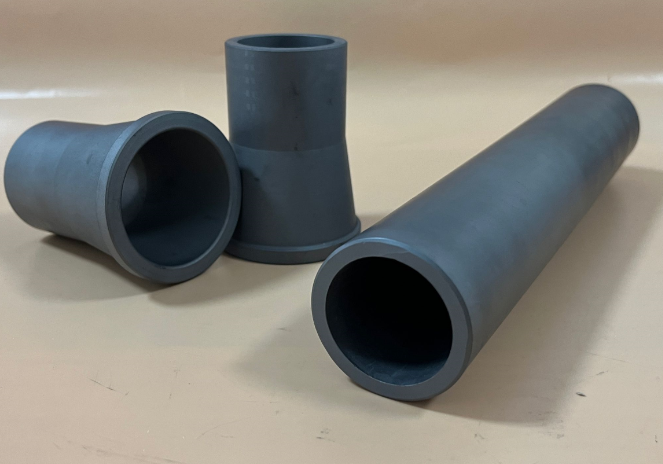

Pressing α-SiC particles with additives and exposing them to liquid silicon in a high-temperature furnace causes the graphite to react with the liquid silicon, forming β-SiC. This β-SiC combines with the α-SiC and the remaining free silicon, which fills any pores. This process results in a high-density material known as reaction-bonded silicon carbide (RBSC). The RBSC we provide has a high density (3.05-3.10 g/cm³) and a low free silicon content (less than 10%), making it suitable for use in seal rings and nozzles exposed to moderately concentrated acids or alkalis.

2.Pressureless sintered silicon carbide

Usually it appears as SSiC or Q1

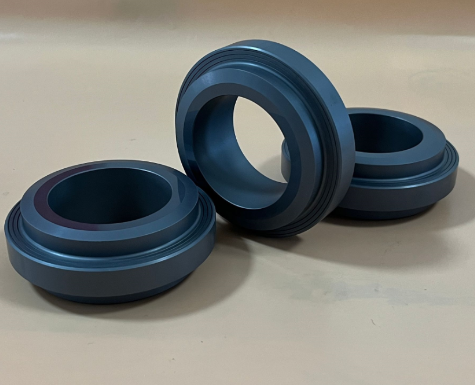

Pressureless sintered silicon carbide, which is sintered with a fine grain size and free of unreacted silicon, exhibits high hardness and strength. It also has excellent oxidation resistance, and withstands high temperatures and corrosion. These properties make it ideal for use in mechanical sealing rings, nozzles, armor plates, and magnetic pumps, particularly in environments with strong acids and alkalis.

3.Graphite loaded sintered silicon carbide

Usually it appears as SSiC+C

Graphite-loaded sintered silicon carbide is produced by incorporating fine graphite particles into the sintered silicon carbide process at high temperatures. This material retains the excellent properties of standard sintered silicon carbide (SSiC), and the graphite particles enhance its self-lubrication and resistance to dry friction. It is suitable for use in high-corrosion, high-load, and dry friction conditions, such as in sliding sleeves or bearings.

4.Porous sintered silion carbide

This material is created by specially optimizing the surface friction properties of SSiC. During sintering, uniform and independent spherical pores are formed. When the sealing surface comes into contact with a fluid medium, these pores act as fluid storage chambers, allowing the medium to serve as a lubricant, thereby reducing surface friction and frictional heat. In situations where the fluid medium is insufficient, the liquid stored in the spherical pores aids in lubrication. Porous SSiC is suitable for challenging conditions with limited lubrication or hard-to-hard face friction, such as water pump seals or sliding bearings.

5.Porous sintered silion carbide

This material incorporates fine graphite particles and spherical pores, combining the superior properties of SSiC, SSiC+C, and porous SSiC. It exhibits excellent dry friction resistance and thermal shock performance. This makes it ideal for demanding applications, particularly in high-performance shield pumps and magnetic pumps.

Due to its excellent physical and chemical properties, silicon carbide demonstrates a wide range of applications in various fields. As manufacturing technology advances, its application scope and market demand are expected to expand continuously.

Shanghai Eheng Precision Technology Co.,LTD

Shanghai Eheng Precision Technology Co.,LTD