ESD-Safe ceramics are materials specifically designed to mitigate the risks associated with Electrostatic Discharge (ESD) in environments where static electricity could potentially damage electronic components.

These ceramics possess properties that allow them to control the dissipation of static charges, protecting sensitive electronics. Key characteristics of ESD-Safe ceramics include:

1. **Conductive Additives:**

- ESD-Safe ceramics often contain conductive additives, such as carbon or metal compounds, which enhance their ability to conduct electricity and dissipate static charges.

2. **Controlled Resistivity:**

- These ceramics have a controlled surface resistivity, striking a balance between allowing a controlled dissipation of static charges and preventing rapid discharges that could harm electronic components.

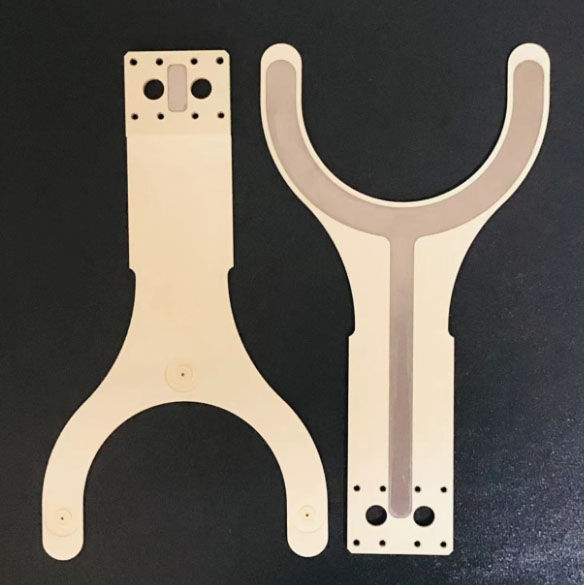

3. **Applications:**

- ESD-Safe ceramics find application in manufacturing facilities, cleanrooms, and other environments where electronic components are handled. They are used in surfaces, flooring, and tools to create ESD-protected workspaces.

4. **Protection Against Electrostatic Discharge:**

- The primary purpose of ESD-Safe ceramics is to prevent electrostatic discharge, protecting electronic devices from damage caused by sudden discharges of accumulated static electricity.

5. **Durable and Wear-Resistant:**

- ESD-Safe ceramics are designed to be durable and resist wear, ensuring a long-lasting solution for ESD protection in various applications.

6. **Compliance with Standards:**

- Adherence to industry standards and regulations is crucial to ensure that ESD-Safe ceramics meet specific criteria for effective electrostatic discharge protection.

7. **Integration in Equipment:**

- ESD-Safe ceramics can be integrated into various equipment and tools to provide localized protection, such as in the construction of workbenches, tabletops, or flooring.

8. **Testing and Maintenance:**

- Regular testing and maintenance are necessary to verify and maintain the ESD-Safe properties of ceramics, ensuring ongoing protection against electrostatic discharge.

By incorporating ESD-Safe ceramics into the design of workspaces and equipment, industries can significantly reduce the risk of damage to electronic components due to electrostatic discharge, ultimately enhancing the reliability and lifespan of sensitive electronic devices.

Shanghai Eheng Precision Technology Co.,LTD

Shanghai Eheng Precision Technology Co.,LTD