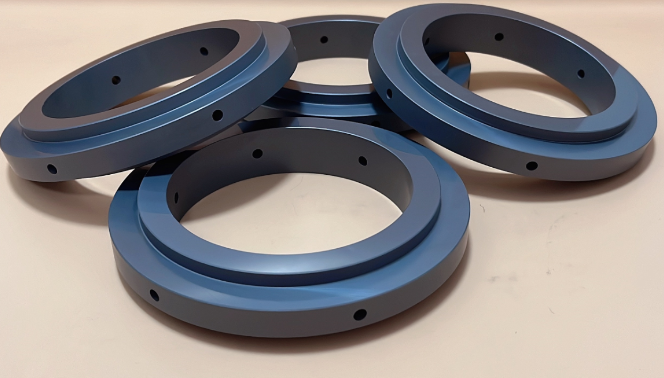

Using silicon carbide faces in mechanical seal assemblies enhances performance and extends seal life, leading to lower maintenance and operating costs for rotating equipment such as turbines, compressors, and centrifugal pumps. Eheng seal faces reduce the risk of leakage and catastrophic failure, protecting the environment from fugitive emissions. They also lower energy consumption by minimizing friction during startup and shutdown and reducing wear and erosion during operation. Eheng seal faces are highly durable, increasing the mean time between failures, which boosts productivity and lowers the total cost of ownership for processing equipment.

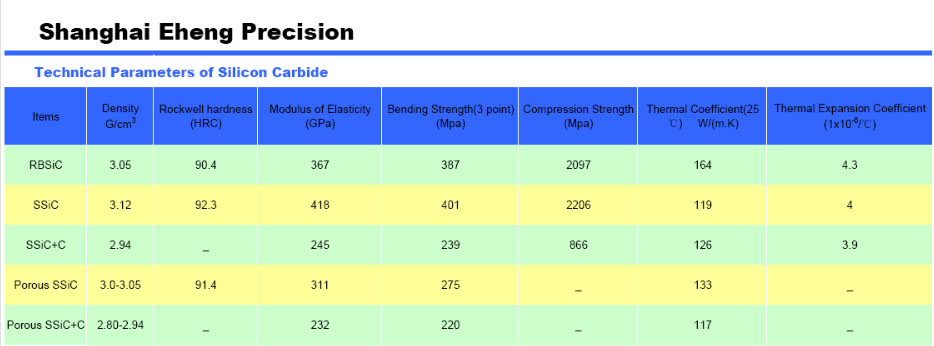

Silicon carbide types and properties

Shanghai Eheng Precision Technology Co.,LTD

Shanghai Eheng Precision Technology Co.,LTD