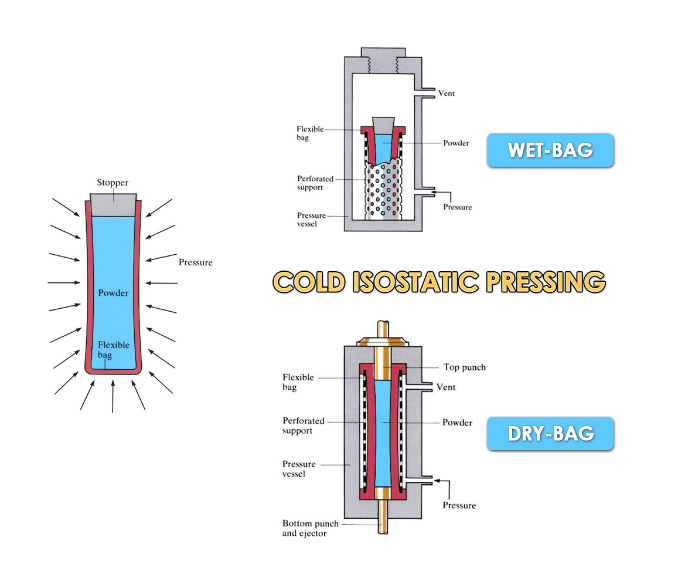

Cold Isostatic Pressing (CIP) is a manufacturing process used to compact powdered materials into specific shapes under high pressure.

The process occurs at room temperature without the application of heat. Two common technologies within CIP are wet bag and dry bag technology.

**Cold Isostatic Pressing:**

- **Objective:** The primary goal is to achieve uniform compaction of powdered materials, such as ceramics or metal powders, by applying equal pressure from all directions.

- **Equipment:** Isostatic presses consist of a pressure vessel or chamber capable of exerting pressure uniformly on the material placed inside a flexible mold or container.

**Wet Bag Technology:**

- **Process:**

- Powder is placed in a flexible rubber mold, forming the shape of the desired end product.

- The mold, often referred to as the "wet bag," is submerged in a liquid medium, typically water or oil.

- Hydraulic pressure is then applied to the liquid in the chamber, transmitting the pressure uniformly to the powder through the flexible mold.

**Dry Bag Technology:**

- **Process:**

- Similar to wet bag technology, powder is placed in a flexible mold.

- However, in dry bag technology, there is no immersion in liquid. The flexible mold containing the powder is directly subjected to hydraulic pressure.

- The absence of liquid contact is particularly useful for materials sensitive to moisture.

**Advantages of Cold Isostatic Pressing:**

- Enables the production of intricate shapes with high precision.

- Maintains material integrity as the process occurs at room temperature.

- Suitable for a variety of materials, including ceramics, metals, and composites.

**Applications:**

- Commonly used in industries such as ceramics manufacturing, powder metallurgy, and the production of complex components for various applications.

In summary, cold isostatic pressing, incorporating both wet and dry bag technologies, provides a versatile and effective method for shaping powdered materials

with the advantage of maintaining material properties due to the absence of heat during the compaction process.

Shanghai Eheng Precision Technology Co.,LTD

Shanghai Eheng Precision Technology Co.,LTD