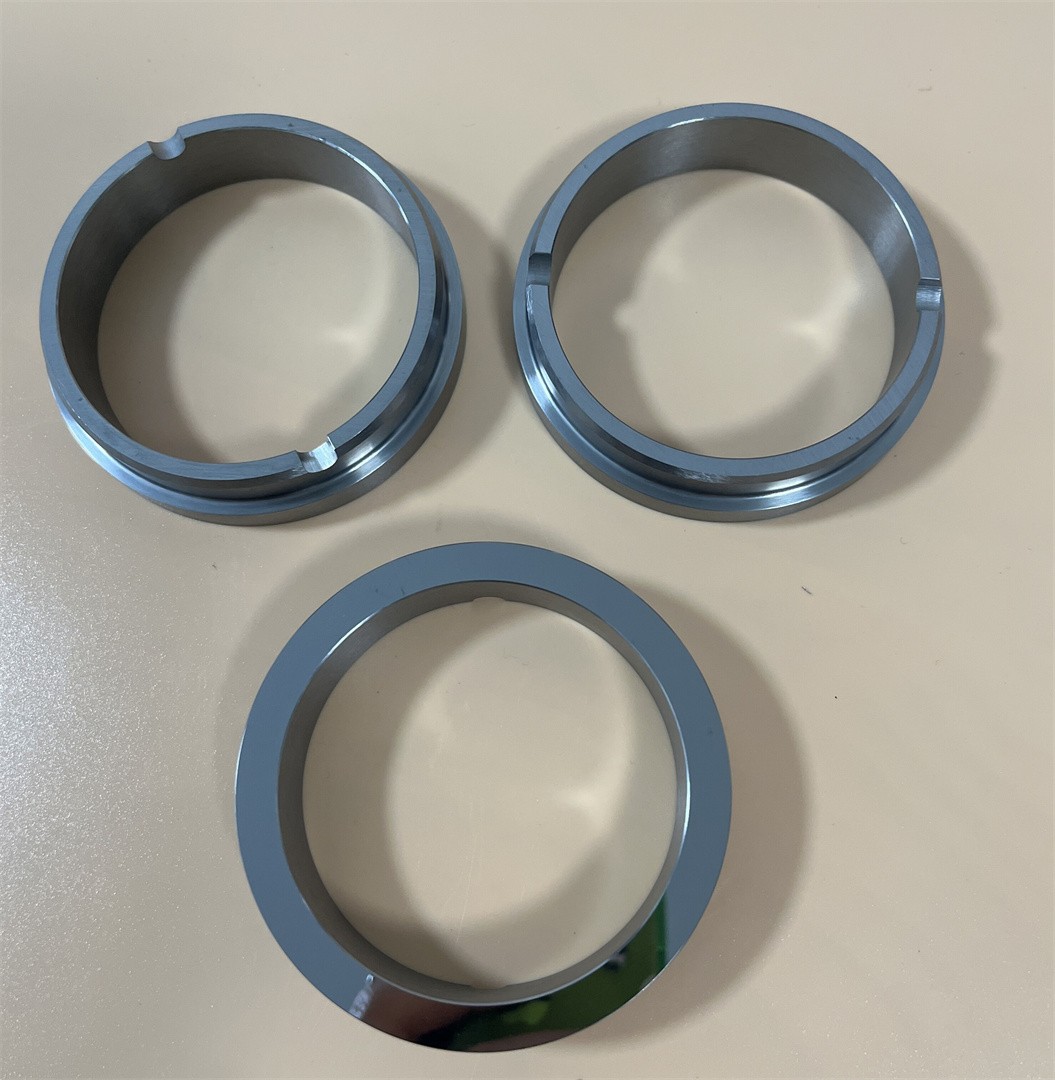

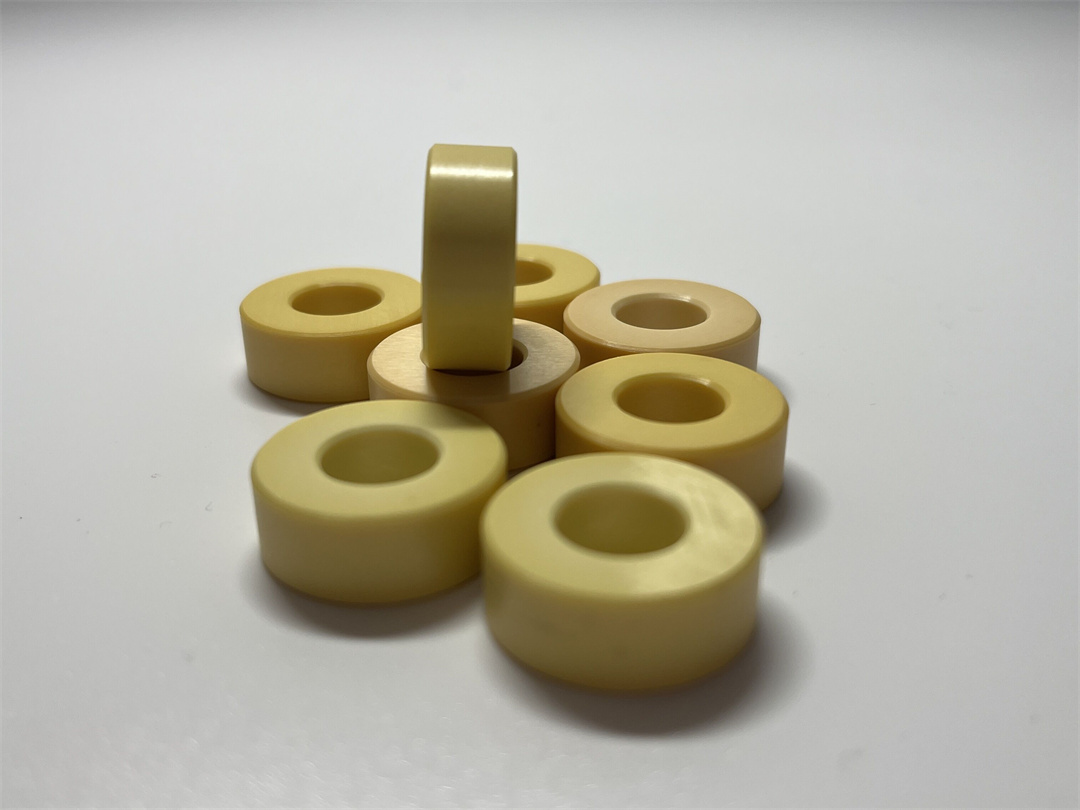

Tungsten carbide seal rings are critical components in mechanical seals, offering several key characteristics that make them well-suited for demanding applications. Here are the main features of Tungsten carbide seal rings:

1. **Hardness:**

- Tungsten carbide is extremely hard, providing exceptional wear resistance. This hardness contributes to the durability and extended lifespan of the seal ring.

2. **Wear Resistance:**

- Tungsten carbide seal rings exhibit excellent resistance to wear, making them suitable for applications involving continuous movement and friction.

3. **High Temperature Stability:**

- Tungsten carbide can withstand high temperatures without significant deformation, making it suitable for use in applications with elevated temperatures.

4. **Chemical Inertness:**

- Tungsten carbide is chemically inert to many substances, providing resistance to corrosion. This characteristic is crucial in applications where exposure to corrosive substances is a concern.

5. **Strength and Toughness:**

- Tungsten carbide combines high hardness with good strength and toughness, allowing it to withstand mechanical stresses without breaking or chipping.

6. **Coefficient of Friction:**

- Tungsten carbide seal rings typically have a low coefficient of friction, contributing to efficient operation and reducing energy consumption during movement.

7. **Dimensional Stability:**

- Tungsten carbide maintains its dimensional stability under various conditions, ensuring consistent performance and preventing deformation or distortion.

8. **Electrical Conductivity:**

- Tungsten carbide is an electrical conductor, and this property can be advantageous in certain applications where electrical conductivity is desired.

9. **Adaptability to Harsh Environments:**

- Tungsten carbide seal rings can operate effectively in harsh environments, including those with abrasive particles, high pressures, and extreme temperatures.

10. **Versatility in Applications:**

- Tungsten carbide is used in a wide range of applications, including mechanical seals, bearings, cutting tools, and other wear-resistant components.

11. **Biocompatibility (for certain grades):**

- In specific medical or bioengineering applications, certain grades of tungsten carbide are biocompatible, making them suitable for use in medical implants or devices.

These characteristics collectively make tungsten carbide seal rings valuable in industries such as manufacturing, oil and gas, chemical processing, and others where reliability, wear resistance, and durability are crucial.

For more details contact us freely.

Shanghai Eheng Precision Technology Co.,LTD

Shanghai Eheng Precision Technology Co.,LTD